Boil & Dry Non-Odor Compost System

Characteristics

The “Boil & Dry Non-Smell Compost System” needs a site space of only one-thirtieth of traditional fermentation systems.

When sludge is treated and processed for fertilizer production by traditional methods, it not only demands a huge treatment area but also causes serious pollution on account of hazardous smells emitted. In the past, these issues have prevented people from taking up the practice of sludge treatment. Given this background, the “Boil & Dry Non-Smell System” can be seen as a kind of fairy godmother.

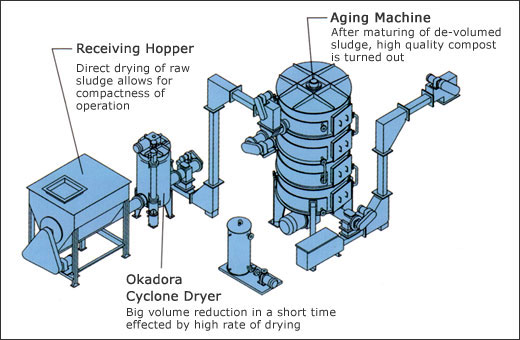

To take a typical example: 300 tons of sludge requiring treatment. With the traditional fermentation method, another 150 tons of water adjustment agent (dried powder) needs to be added, making a total quantity for fermentation of 450 tons. This can be converted into 700 m3 or more in volume. In addition, it takes 60 days for the fermentation process, and also requires a 60 times wider space for storage, with 50 cms in height, thus making a total demand on space of 9,100 m2. It is almost unimaginable when we consider that such a huge space continuously produces hazardous smells caused by anaerobic fermentation. On the other hand, with the “Boil & Dry Non-Smell Compost System”, initial processing takes place in the Okadora Cyclone Dryer, which reduces the weight from 300 tons down to 110 tons, making a total of just 168 m3 in volume to be fermented. Additionally, the fermentation process takes a maximum of 10 days, making a quantity for storage purposes of just 10 times. As a consequence, the required space for fermentation is just 300 m2 – i.e. 1/30 of that needed for the traditional fermentation system.

It is clear that the Okadora “Boil & Dry Non-Smell Compost System” is by far the best solution for recycling sludge into organic fertilizer.