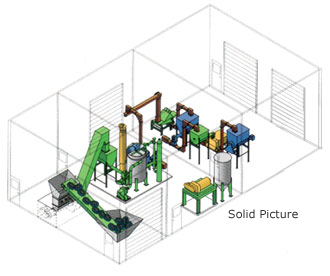

Industrial Waste Intermediary Treatment

Employing a non-polluting process, waste tires are separated to oil, carbon and steel in 60 minutes.

With the employment of a gas cooling system, it is not required to obtain an environmental assessment; therefore an immediate installation is possible. The Okadora Carbonizing Plant employs a system of non-oxygen thermal cracking and so no dioxins are produced at all. Normally, when tires are burnt, black smoke and sulfur oxides are emitted but there are no such emissions with the Okadora Carbonizing Plant. The carbonized product, through a secondary treatment, is recycled for soil remediation, while collected oil is for supplementary fuel, and the steel can be reprocessed in the steel industry.